Application of Knowledge Engineering in Sports Protective Gear Design: A Study on Innovative Methods Based on Extension Theory

Abstract:

This study, rooted in extension theory and the principles of knowledge engineering, explores and formulates a novel method for generating sports protective gear designs. Given the critical role of sports protective gear in safeguarding athletes from injuries, coupled with escalating demands for product quality, the aim is to uncover a more effective approach to innovative design. This method involves formalizing modeling of various elements in the design process and representing this information in the elemental form of knowledge engineering. Through the related analysis, divergent analysis, as well as permutation and conduction transformations of these elements, innovative design schemes for sports protective gear are generated. This process not only optimizes design schemes in depth but also ventures into new design methods and processes. The objective is to offer a novel perspective in integrating extension theory and knowledge engineering in the design of sports protective gear, aspiring to provide more effective strategies to enhance existing design workflows. The goal of this new design method is to produce sports protective gear that is both practical and innovative, thereby enhancing the safety and enjoyment of athletes.

1. Introduction

Sports protective gear serves as wearable equipment designed to shield athletes from injuries during physical activities. With the growing number of sports enthusiasts, the demand for sports protective gear has also increased, alongside heightened expectations for product quality. In China, the innovative design of sports protective gear is in a developmental stage, with most design processes heavily reliant on designers' experience and intuition. This reliance often results in uncertainty in design outcomes and reveals a lack of research in design methodologies. Existing studies on sports protective gear primarily focus on utility research and product development. For instance, Wu et al. [1] have utilized three-dimensional dynamic capture technology to measure the momentum buffering capacity of various wrist guards based on the principle of energy conservation, thereby assessing the protective performance of three types of wrist guards. Yu and Zhang [2] have studied the application of fiber material buffer protectors in sports training. Maurel et al. [3] designed a new wrist guard product that maintains qualified protective performance while enhancing the flexibility of the user's wrist and fingers, as verified through testing.

To address the gaps in current research, knowledge engineering methods can be employed to optimize the design of sports protective gear. Knowledge engineering, an interdisciplinary field, primarily investigates how to use computers and other technologies to simulate and extend human knowledge processing capabilities, especially in information acquisition, processing, storage, and application. In sports protective gear design, the application of knowledge engineering techniques such as data mining, machine learning, and artificial intelligence can extract valuable information from vast amounts of user feedback and product testing data. This, in turn, guides designers in making more scientific decisions. This not only aids in enhancing the functionality and comfort of sports protective gear but also increases its market competitiveness.

American LP protective gear, based on human physiological characteristics and relevant theories, has established an ideal pressure map suitable for various body parts. By following the body's ideal pressure curve and applying graded pressure to different body parts, the gear developed with layered pressure technology can effectively suppress internal factors affecting bodily coordination, improve users' control over their movements, and maintain physical health, as illustrated in Figure 1. In summary, various protective gears offer effective protection, and their protective effects vary. Therefore, in sports activities, selecting appropriate gear according to different sports needs is crucial to enhance body protection.

Extension theory, a formalized model studying the possibilities and methods of extending and innovating things [4], has integrated with many fields over the years. In sports protective gear design, combining extension theory and knowledge engineering can create a new design approach. Using methods from extension theory, such as analyzing and solving contradictions in design, along with data analysis and pattern recognition technologies from knowledge engineering, can effectively address complex problems in design and innovate design thinking. For instance, Li et al. [5] have used extension comprehensive evaluation to extract key design elements of car front facades, addressing issues of ambiguity, complexity, and subjectivity in the extraction process. Similarly, these techniques can be used for more accurate extraction and assessment of key elements in sports protective gear design. Li et al. [6] have studied the relationship between individualized needs and product functions, working on personalized product design based on extension innovative methods, enabling personalized redesign of existing products. Liang and Yang [7] have proposed methods for constructing initial extension models for open-ended problems and solving single-target open-ended problems using extension analysis and extension transformation methods.

To date, extension theory has been widely applied in relevant engineering fields [8], [9], [10], [11], but its incorporation into sports protective gear design remains unexplored. In the innovative design of new sports protective gear schemes, applying extension theory and knowledge engineering can formalize the resolution of contradictions, leading to new design methods and optimized design processes. The sports protective gear schemes developed with these new methods are not only practical and innovative but also enhance the safety and enjoyment of athletes in sports activities. Therefore, this paper, based on extension theory [12], [13], [14], investigates a novel method for generating sports protective gear schemes.

2. Novel Sports Protective Gear Design Method Based on Extension Theory

In the process of designing novel sports protective gear based on extension theory, the basic unit used to describe sports protective gear is referred to as a “sports protective gear element”. These elements are primarily employed to represent information involved in innovative design. Any described object comprises multiple characteristics and their corresponding values. Elements can be symbolically expressed, as shown in Eq. (1):

where, $O$ represents the information involved in the design process of sports protective gear; ${{c}_{1}}{{c}_{2}}\ldots {{c}_{n}}$ signify the $n$ characteristics of the gear, and ${{v}_{1}}{{v}_{2}}\ldots {{v}_{n}}$ denote the values corresponding to the above characteristics. Depending on the object of description, a sports protective gear element $B$ can be categorized into material element $M$, relation element $R$, and event element $A$.

Any sports protective gear ${{O}_{m}}$ possesses conjugacy, characterized by its real part $\text{re}\left( {{O}_{m}} \right)$ and imaginary part $\text{im}\left( {{O}_{m}} \right)$, soft part $\text{sf}\left( {{O}_{m}} \right)$ and hard part $\text{hr}\left( {{O}_{m}} \right)$, latent part $\text{lt}\left( {{O}_{m}} \right)$ and manifest part $\text{ap}\left( {{O}_{m}} \right)$, positive part $\text{p}{{\text{s}}_{c}}\left( {{O}_{m}} \right)$ and negative part $\text{n}{{\text{g}}_{c}}\left( {{O}_{m}} \right)$. These aspects respectively reflect the materiality, systematicity, dynamism, and opposition of sports protective gear. Moreover, they interact and transform into each other. In the innovative design of sports protective gear, one can start from these four aspects for a comprehensive understanding of the product. Each conjugate part and its corresponding intermediary sum up to the sports protective gear itself. The conjugacy of sports protective gear can be depicted through a model, as illustrated in Figure 2.

Based on user needs and dissatisfaction, the functional shortcomings of existing sports protective gear are enumerated. Through formalized modeling, these functional flaws are expressed using elements, resulting in the creation of event elements representing the shortcomings of sports protective gear products, as shown in Eq. (2):

where, $A_{01},A_{02},...,A_{0m2}$ represent the event elements derived from the enumerated shortcomings related to the insufficient functionality of sports protective gear [9].

Due to the existence of certain connections between things, transforming one element of sports protective gear during the design process can cause changes in related elements. In the process of refining and optimizing the design for functional shortcomings of sports protective gear, existing inadequacies in functionality cannot be resolved out of thin air. Since the functionality is related to the physical components and the interrelations between these components, resolving functional deficiencies necessitates addressing the physical and structural defects first. These physical and structural defects are then modeled as elements, known respectively as deficiency material elements and deficiency relation elements.

The deficiency material elements of sports protective gear can be expressed using an elemental model, as shown in Eq. (3).

where, $M_{01}, M_{02},..., M_{0n1}$ represent the deficiency material elements derived from the defects in the product's physical aspects.

The deficiency relation elements of sports protective gear can be expressed using an elemental model, as shown in Eq. (4):

where, $R_{01}, R_{02},..., R_{0n1}$ represent the deficiency relation elements derived from the defects in the product's structural aspects.

The divergent analysis of new sports protective gear refers to starting from a single deficiency element of sports protective gear and expanding it into multiple elements. This provides various selectable approaches to meet user needs and improve product flaws, leading to multiple design schemes for new sports protective gear. The main rules of divergent analysis include:

where, “$\mapsto$” represents the divergent symbol for sports protective gear elements.

The divergent analysis of the deficiency material elements and deficiency relation elements of existing sports protective gear, as discussed in the previous sections, can only suggest pathways for innovative design. To achieve designs that meet user needs, extension transformations must be implemented. Through certain extension transformations, product defects can be converted into elements that satisfy users, or even become strengths of the product.

Extension transformations aimed at innovative sports protective gear design refer to the transformations applied to sports protective gear elements based on the results of the related and divergent analyses. These mainly include permutation transformation and conduction transformation [9].

(1) Permutation transformations aimed at new sports protective gear design involve the transformation of the value, characteristic, or object of the deficiency material elements or deficiency relation elements of sports protective gear. The main rules are as follows:

where, $B$ represents the deficiency elements involved in the design process, $T$ denotes the transformation applied to $B$, and $B^{\prime}$ is the new sports protective gear element obtained after the transformation.

(2) Conduction transformation refers to the changes in related elements caused by the transformation of a particular deficiency element of sports protective gear. It mainly involves the active transformation of the deficiency material elements and deficiency relation elements of sports protective gear, leading to the conduction transformation of the event elements related to functional deficiencies. This can be understood as the conduction transformation of the object sports protective gear elements.

Considering that sports protective gear is designed to reduce the likelihood of injuries during physical activities, multiple factors must be considered during its design. Ideally, sports protective gear should be a complete flexible system with excellent protective performance, reliable safety features, ease of wear, comfortable fit, adaptability to the human body, and the ability to provide appropriate assistance or data feedback functionalities. However, not every design scheme generated in the divergent process of creative solutions meets user needs. Therefore, certain criteria must be applied to converge these creative solutions, leading to innovative sports protective gear designs.

3. Practice of New Sports Protective Gear Design Method Based on Extension Theory

Innovative design is inseparable from understanding needs. Focusing on post-90s basketball enthusiasts and their use of sports knee protectors, an analysis is conducted around the product and user group. By analyzing knee protectors available on the market and combining the characteristics of basketball and the physiological structure of the knee joint, design criteria for sports knee protectors are refined. These criteria mainly include functionality, comfort, and convenience. The design criteria for sports knee protectors are shown in Table 1.

Category | Specific Description |

Type | Soft knee protectors, semi-soft knee protectors, hard knee protectors, others (patellar straps, muscle tapes) |

Function | Impact buffering, patellar compression, landing cushioning, restriction of abnormal joint angles, slip resistance |

Comfort | Contact comfort, size fit, air permeability, moisture absorption |

Convenience | Ease of wearing and removal |

Structure | Lateral support components, anti-slip structure, wearing structure, front cushioning pads |

Appearance | Design aspects, material combinations, colors and patterns |

Trend | Use of new materials, technologies, and forms to enhance protection, comfort, and convenience; trend towards intelligent products |

To gather data on the needs of target users, surveys were conducted, and an analysis of user needs was performed based on emotional design principles, as shown in Table 2.

Emotional Design Level | Need Category | Need Description | Satisfaction Description |

Instinctual Layer | Sensory Needs | Streamlined design; innovative styles; suitable colors; comfortable materials | Limited style differentiation for different groups; homogeneity in design and color |

Behavioral Layer | Wearability Needs | Convenient to put on and take off | Difficulty in wearing and removal |

Functional Needs | Superior protection; integration of new functions (assistance in training, health monitoring, motion support, gait detection, etc.) | Too simplistic in functionality | |

Experience Needs | Suitable sizing, good structural fit; sweat absorption, air permeability; comfortable material contact | Improper sizing, tightness at wrong places, overly rigid structure causing discomfort; too thick and hot | |

Reflective Layer | Aesthetic Needs | Simplicity, fashion, futuristic, sporty, mechanical feel | Lack of means to express emotions |

Emotional Needs | Personalization; individual emotional expression; cultural connotations |

Applying Eq. (1), elements of sports knee protectors can be modeled.

Assuming the real part of the sports knee protector is represented as a material element ${{M}_{re}}$, the results are as follows:

$M_{r e}=\left[\begin{array}{lll}\text { Sports Knee Protector, } & \text { Cost, } & 50 \\ & \text { Color, } & \text { Blue, White } \\ & \text { Material, } & \text { Polyester Fiber } \\ & \text { Craftsmanship, } & \text { Knitting } \\ & \text { Pattern, } & \text { Geometric Shapes } \\ & \text { Size, } & 280 \mathrm{~mm} \\ & \text { Style, } & \text { Slip - on Style }\end{array}\right]$

Assuming the imaginary part of the sports knee protector is also represented as a material element ${{M}_{im}}$, the results are as follows:

$M_{i m}=\left[\begin{array}{lll}\text { Sports Knee, } & \text { Brand, } & \text { Brand } \\ & \text { Brand Value, } & \text { High } \\ & \text { Popularity, } & \text { Moderate } \\ & \text { User Rating, } & \text { Good } \\ & \text { Reputation, } & \text { Good } \\ & \text { Related Technique, } & \text { 3D Knitting }\end{array}\right]$

Assuming the hard part of the sports knee protector is represented as a material element ${{M}_{hr}}$, the results are as follows:

$M_{h r 1}=\left[\begin{array}{lll}\text { Front Compression Component, } & \text { Material, } & \text { Silicone } \\ & \text { Protection Area, } & \text { Patella } \\ & \text { Color } & \text { Translucent } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Rounded } \\ & \text { Structural Form, } & \text { Solid Ring }\end{array}\right]$

$M_{h r 2}=\left[\begin{array}{lll}\text { Side Support Component, } & \text { Material, } & \text { Metal } \\ & \text { Color, } & \text { Metallic Natural Color } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Smooth } \\ & \text { Structural Form, } & \text { Spring }\end{array}\right]$

$M_{h r 3}=\left[\begin{array}{lll}\text { Outer Main Body, } & \text { Material, } & \text { Cotton } \\ & \text { Color, } & \text { White }\end{array}\right]$

$\begin{aligned} & M_{h r 4}=[\text { Inner Material, Material, Cotton }] \\ & M_{h r 5}=\left[\begin{array}{lll}\text { Anti-slip Component, } & \text { Material, } & \text { Silicone } \\ & \text { Shape, } & \text { Dotted }\end{array}\right] \\ & M_{h r 6}=[\text { Binding Component, Usage Method, Sleeve ] } \\ & M_{h r 7}=\left[\begin{array}{lll}\text { Decorative Pattern }, & \text { Theme, } & \text { Simple } \\ & \text { Craftsmanship, } & \text { Knitting }\end{array}\right] \\ & \end{aligned}$

When analyzing the soft part of the sports knee protector, which involves the relationships between components as well as between components and the human body/environment, this study takes the front view as the reference point. The soft part is represented as a relation element $R_{sf}$, the results are as follows:

$R_{s f 1}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Outer Main Body } \\ & \text { Back Item, } & \text { Front Compression Component } \\ & \text { Method, } & \text { Fitting } \\ & \text { Degree, } & \text { Close }\end{array}\right]$

$R_{s f 2}=\left[\begin{array}{lll}\text { Left and Right Relationship, } & \text { Outer Side Item, } & \text { Outer Main Body } \\ & \text { Inner Side Item, } & \text { Side Support Component } \\ & \text { Method, } & \text { Encasing }\end{array}\right]$

$R_{s f 3}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Front Compression Component } \\ & \text { Back Item, } & \text { Inner Material } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

$R_{s f 4}=\left[\begin{array}{lll}\text { Left and Right Relationship, } & \text { Outer Side Item, } & \text { Outer Main Body } \\ & \text { Inner Side Item, } & \text { Inner Material } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

$R_{s f 5}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Inner Material } \\ & \text { Back Item, } & \text { Knee } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

$R_{s f 6}=\left[\begin{array}{lll}\text { Left and Right Relationship, } & \text { Outer Side Item, } & \text { Inner Material } \\ & \text { Inner Side Item, } & \text { Side of the Knee Joint } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

$R_{s f 7}=\left[\begin{array}{lll}\text { Top and Bottom Relationship, } & \text { Top Item, } & \text { Binding Component } \\ & \text { Bottom Item, } & \text { Front Compression Component } \\ & \text { Method, } & \text { Separate }\end{array}\right]$

$R_{s f 8}=\left[\begin{array}{lll}\text { Top and Bottom Relationship, } & \text { Top Item, } & \text { Binding Component } \\ & \text { Bottom Item, } & \text { Side Support Component } \\ & \text { Method, } & \text { Separate }\end{array}\right]$

$R_{s f 9}=\left[\begin{array}{lll}\text { Encasing Relationship, } & \text { Outer Side Item, } & \text { Anti-slip Component } \\ & \text { Inner Side Item, } & \text { Human Thigh } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

$R_{s f 10}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Decorative Pattern } \\ & \text { Back Item, } & \text { Outer Main Body } \\ & \text { Method, } & \text { Covering }\end{array}\right]$

To model the deficiencies in the functional aspects of sports knee protectors, the deficiency event elements of sports knee protectors can be represented using elements as follows:

$ A_0=\left\{A_{01}, A_{02}, \ldots, A_{011}\right\}; $

where,

$A_{01}=\left[\begin{array}{lll}\text { Impact Protection, } & \text { Dominant Object, } & \text { Knee } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized or Maintained }\end{array}\right]$

$A_{02}=\left[\begin{array}{lll}\text { Compression, } & \text { Dominant Object, } & \text { Knee Joint } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized or Maintained }\end{array}\right]$

$A_{03}=\left[\begin{array}{lll}\text { Landing Cushioning, } & \text { Dominant Object, } & \text { Knee Joint } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized }\end{array}\right]$

$A_{04}=\left[\begin{array}{lll}\text { Prevention of Excessive, } & \text { Dominant Object, } & \text { Knee } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized or Maintained }\end{array}\right]$

$A_{05}=\left[\begin{array}{lll}\text { Contact Comfort, } & \text { Dominant Object, } & \text { Skin } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, }, & \text { To be Optimized }\end{array}\right]$

$A_{06}=\left[\begin{array}{lll}\text { Permeability and Heat Dissipation, } & \text { Dominant Object, } & \text { Skin } \\ & \text { Acting Object }, & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized }\end{array}\right]$

$A_{07}=\left[\begin{array}{lll}\text { Prevent Slippage, } & \text { Dominant Object, } & \text { User } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized }\end{array}\right]$

$A_{08}=\left[\begin{array}{lll}\text { Quick and Easy Wear and Removal, } & \text { Dominant Object, } & \text { Knee Joint } \\ & \text { Acting Object, } & \text { User } \\ & \text { Level of Optimization, } & \text { Innovation Required }\end{array}\right]$

$\begin{aligned} & A_{09}=\left[\begin{array}{lll}\text { MeetingAestheticNeeds, } & \text { Dominant Object, } & \text { User } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { To be Optimized }\end{array}\right] \\ & A_{010}=\left[\begin{array}{lll}\text { Sports Assistance, } & \text { Dominant Object, } & \text { Lower Limbs } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { InnovationRequired }\end{array}\right] \\ & A_{011}=\left[\begin{array}{lll}\text { Providing, } & \text { Dominant Object, } & \text { SportsData } \\ & \text { Acting Object, } & \text { Knee Protector } \\ & \text { Level of Optimization, } & \text { InnovationRequired }\end{array}\right] \\ & \end{aligned}$

Based on the knowledge from biomechanics, structural science, and materials science, combined with the models of real-imaginary conjugate pairs and hard-soft conjugate pairs, the related relationships of the deficiency event elements of sports knee protectors are established as follows:

$\left\{\begin{array}{l}A_{01} \wedge A_{02} \sim M_{h r 1} \vee R_{s f 1} \\ A_{03} \wedge A_{04} \sim M_{h r 2} \vee R_{s f 2} \\ A_{05} \wedge A_{06} \sim M_{h r 3} \vee M_{h r 4} \\ A_{07} \sim M_{h r 5} \vee M_{h r 6} \vee R_{s f 9} \\ A_{08} \sim M_{h r 6} \vee M_{r e 1} \\ A_{09} \sim M_{h r 1} \vee M_{h r 2} \vee M_{h r 3} \vee M_{h r 7} \vee R_{s f 10} \\ A_{010} \vee A_{011} \sim M_{h r 8}\end{array}\right.$

where, “$\sim$” is the symbol for correlation.

From the above analysis of the deficiency basic elements of sports knee protectors, we can identify the deficiency material elements and deficiency relation elements. For clarity in subsequent research processes, these deficiency elements are expressed in a standardized form, ensuring a one-to-one correspondence. Applying Eq. (3), the deficiency material elements are represented using elements as follows:

$M_0=\left\{M_{01}, \ldots, M_{0 m 1}, \ldots, M_{0 n 1}\right\}=\left\{M_{r e 1}, M_{h r 1}, M_{h r 2}, M_{h r 3}, M_{h r 4}, M_{h r 5}, M_{h r 6}, M_{h r 7}, M_{h r 8}\right\};$

$M_{01}=M_{r e 1}=[\begin{array}{lll} Sports\text{ }Knee\text{ }Protector,& Style,& Sleeve \end{array}];$

$M_{09}=M_{h r 8}=[\begin{array}{lll} Additional\text{ }Components,& None,& None \end{array}];$

Applying Eq. (4), the deficiency relation elements are represented using elements as:

$R_0=\left\{R_{01}, \ldots, R_{0 m 1}, \ldots, R_{0 n 1}\right\}=\left\{R_{s f 1}, R_{s f 2}, R_{s f 5}, R_{s f 9}\right\}$

(1) Taking sports knee protectors as the practical object, where, “$\mapsto$” represents the divergent symbol for sports protective gear elements, the divergent analysis process of deficiency material elements is as follows (due to space constraints, only a subset of divergent rules are applied for analysis):

The deficiency material element $M_{01}$, applying Eq. (7), yielded the following divergent analysis results:

$M_{01}=[$ Basketball Knee Protectors , Style, Sleeve Style$] \mapsto\left\{\begin{array}{l}M_{011}=[\text {Basketball Knee Protectors , Style, Semi-open Style}] \\ M_{012}=[\text {Basketball Knee Protectors , Style, Wrap-around Style}]\end{array}\right.$

The deficiency material element $M_{02}$, applying Eq. (7), yielded the following divergent analysis results:

$M_{02}=\left[\begin{array}{lll}\text { Front Compression Component, } & \text { Material, } & \text { Silicone } \\ & \text { Protection Area, } & \text { Patella } \\ & \text { Color, } & \text { Translucent } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Rounded } \\ & \text { Structural Form, } & \text { Solid Ring }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}M_{021}=\left[\begin{array}{lll}\text { Front Compression Component, } & \text { Material, } & \text { Plant Fiber } \\ & \text { Protection Area, } & \text { Patella } \\ & \text { Color, } & \text { Natural Color } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Rounded } \\ & \text { Structural Form, } & \text { Solid Block }\end{array}\right] \\ M_{022}=\left[\begin{array}{lll}\text { Front Compression Component, } & \text { Material, } & \text { Gas } \\ & \text { Protection Area, } & \text { Patella } \\ & \text { Color, } & \text { None } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Rounded } \\ & \text { Structural Form, } & \text { Airbag }\end{array}\right] \\ M_{023}=\left[\begin{array}{lll}\text { Front Compression Component, } & \text { Material, } & \text { Non-Newtonian Fluid } \\ & \text { Protection Area, } & \text { Patella } \\ & \text { Color, } & \text { Orange } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Technological Feel } \\ & \text { Structural Form, } & \text { Solid Filling }\end{array}\right]\end{array}\right.$

The deficiency material element $M_{03}$, applying Eq. (7), yielded the following divergent analysis results:

$M_{03}=\left[\begin{array}{lll}\text { Side Support Component, } & \text { Material, } & \text { Metal } \\ & \text { Color, } & \text { Metallic Natural Color } \\ & \text { Inner Design, } & \text { Smooth } \\ & \text { Outer Design, } & \text { Smooth } \\ & \text { Structural Form, } & \text { Spring }\end{array}\right] \mapsto$

$\left\{\begin{aligned} M_{031}=\left[\begin{array}{rl}\text { Side Support Component, Material, Bamboo } \\ \text { Color , Natural Material Color} \\ \text { Inner Design, Flat } \\ \text { Outer Design, Rounded} \\ \text { Structural Form , Solid }\end{array}\right]\\ M_{032}=\left[\begin{array}{rl}\text { Side Support Component, Material, Metal } \\ \text { Color , Silver } \\ \text { Inner Design, Flat } \\ \text { Outer Design, Technological Feel} \\ \text { Structural Form, Mechanical Structure }\end{array}\right]\end{aligned}\right.$

To optimize the deficiency material element $M_{04}$, applying Eq. (7), the divergent analysis results are as follows:

$M_{04}=\left[\begin{array}{lll}\text { Outer Main Body, } & \text { Material, } & \text { Cotton } \\ & \text { Color, } & \text { White }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}M_{041}=\left[\begin{array}{ll}\text { Outer Main Body, } & \text { Material, } A B S \\ & \text { Color, Silver }\end{array}\right] \\ M_{042}=\left[\begin{array}{ll}\text { Outer Main Body, } & \text { Material, Nylon } \\ & \text { Color, Black }\end{array}\right] \\ M_{043}=\left[\begin{array}{ll}\text { Outer Main Body, Material, Bamboo Charcoal } \\ \text { Color, Blue }\end{array}\right] \\ M_{044}=\left[\begin{array}{ll}\text { Outer Main Body, } & \text { Material, Polyester } \\ & \text { Color, Green }\end{array}\right]\end{array}\right.$

To optimize the deficiency material element $M_{05}$, applying Eq. (7), the divergent analysis results are as follows:

$M_{05}=[$ Inner Material, Material, Cotton $] \mapsto\left\{\begin{array}{l}M_{051}=[\text { Cotton, Material, Polyester Fiber }] \\ M_{052}=[\text { Cotton, Material, Lycra }]\end{array} \right.$

To enhance the contact comfort of the deficiency material element $M_{06}$, applying Eqs. (5) and (7), the divergent analysis results are as follows:

$M_{06}=\left[\begin{array}{lll}\text { Anti-slip Component, } & \text { Material, } & \text { Silicone } \\ & \text { Shape, } & \text { Dotted }\end{array}\right] \mapsto$$\left\{\begin{array}{l}M_{061}=\left[\begin{array}{ll}\text { Anti-slip Component, } & \text { Material, Silicone } \\ & \text { Shape, Stepped } \\ & \text { Area, Moderate }\end{array}\right] \\ M_{062}=\left[\begin{array}{ll}\text { Anti-slip Component, } & \text { Material, Rubber } \\ & \text { Shape, Wavy } \\ & \text { Area, Large }\end{array}\right]\end{array}\right.$

For optimizing the usage method of binding components to make them more convenient, applying Eq. (7) to the deficiency material element $M_{07}$, the divergent analysis results are as follows:

$\begin{aligned} & M_{07}=[\text { Binding Component, Usage Method, Sleeve }] \mapsto \\ & \left\{\begin{array}{l}M_{071}=\left[\begin{array}{ll}\text { Binding Component, } & \text { Usage Method, Magnetic Attraction }]\end{array}\right] \\ M_{072}=\left[\begin{array}{lll}\text { Binding Component, } & \text { Usage Method, Intelligent Tightening }]\end{array}\right] \\ M_{073}=\left[\begin{array}{lll}\text { Binding Component, } & \text { Usage Method, Inflatable Compression }\end{array}\right] \\ M_{074}=\left[\begin{array}{l}\text { Binding Component, Usage Method, Velcro }\end{array}\right]\end{array}\right.\end{aligned}$

The deficiency material element $M_{08}$ should align more with user aesthetics and offer diverse appearances. Applying Eq. (7), the divergent analysis results for aesthetic compliance are as follows:

$M_{08}=\left[\begin{array}{lll}\text { Decorative Pattern }, & \text { Theme, } & \text { Simple } \\ & \text { Craftsmanship, } & \text { Knitting }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}M_{081}=\left[\begin{array}{ll}\text { Decorative Pattern, } & \text { Theme, Simple } \\ & \text { Craftsmanship, Knitting }\end{array}\right] \\ M_{082}=\left[\begin{array}{ll}\text { Decorative Pattern, } & \text { Theme, Fashionable } \\ & \text { Craftsmanship, Spray Painting }\end{array}\right] \\ M_{083}=\left[\begin{array}{ll}\text { Decorative Pattern, } & \text { Theme, Sporty Feel } \\ & \text { Craftsmanship, Spray Painting }\end{array}\right]\end{array}\right.$

Diverging the deficiency material element $M_{09}$ towards new functionalities that the novel sports knee protectors could offer, applying Eq. (5), yields the following results:

$M_{09}=[$ Additional Components, None, None $] \mapsto$

$\left\{\begin{array}{l}M_{091}=[\text { Additional Components, Sensor Type , Flexible Pressure Sensor }] \\ M_{092}=\text { [Additional Components, Principle of Sports Assistance Component, Electrical Stimulation }] \\ M_{093}=[\text { Additional Components, Principle of Sports Assistance Component, Physical Support }]\end{array}\right.$

(2) Divergent Analysis of Deficiency Relation Elements in Sports Protective Gear

By performing divergent analysis on $R_{01}$ and applying Eqs. (5)-(8), the divergent analysis results are attained as follows:

$R_{01}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Outer Main Body } \\ & \text { Back Item, } & \text { Front Compression Component } \\ & \text { Method, } & \text { Fitting }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{011}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Front Item, Front Compression Component } \\ & \text { Back Item, Outer Main Body } \\ & \text { Method, Fitting }\end{array}\right] \\R_{012}=\left[\begin{array}{ll}\text { Encasing Relationship, } & \text { Outer Side Item, Outer Main Body } \\ & \text { Inner Side Item, Front Compression Component } \\ & \text { Method, Left and Right Parts Connection }\end{array}\right] \\R_{013}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Front Item, Sports Assistance Component } \\ & \text { Back Item, Knee } \\ & \text { Method, Fitting }\end{array}\right] \\ \end{array}\right.$

$R_{011}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Front Compression Component } \\ & \text { Back Item, } & \text { Outer Main Body } \\ & \text { Method, } & \text { Fitting }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{0111}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Front Item, Outer Main Body } \\ & \text { Back Item, Binding Component } \\ & \text { Method, Partial Connection}\end{array}\right] \\R_{0112}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Outer Side Item, Front Compression Component } \\ & \text { Back Item, Binding Component} \\ & \text { Method, Separated }\end{array}\right] \\R_{0113}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Front Item, Side Support Component } \\ & \text { Back Item, Binding Component } \\ & \text { Method, Separated}\end{array}\right] \\ \end{array}\right.$

$R_{012}=\left[\begin{array}{lll}\text { Encasing Relationship, } & \text { Outer Side Item, } & \text { Outer Main Body } \\ & \text { Inner Side Item, } & \text { Front Compression Component } \\ & \text { Method, } & \text { Peripheral Connection }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{0121}=\left[\begin{array}{ll}\text { Encasing Relationship, } & \text {Outer Side Item, Outer Main Body} \\ & \text { Inner Side Item, Front Compression Component} \\ & \text { Method, Left and Right Parts Connection}\end{array}\right] \\R_{0122}=\left[\begin{array}{ll}\text { Encasing Relationship, } & \text { Outer Side Item, Binding Component } \\ & \text { Inner Side Item, Outer Main Body} \\ & \text {Method, Fitting}\end{array}\right] \\R_{0123}=\left[\begin{array}{ll}\text { Encasing Relationship, } & \text { Outer Side Item, Sensor Component } \\ & \text { Inner Side Item, Outer Main Body } \\ & \text { Method, Embedded}\end{array}\right] \\ \end{array}\right.$

$R_{013}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Sports Assistance Component } \\ & \text { Back Item, } & \text { Knee } \\ & \text { Method, } & \text { Fitting }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{0131}=\left[\begin{array}{ll}\text { Front and Back Relationship, } & \text { Front Item, Front Compression Component} \\ & \text { Intermediate Item, Inner Material } \\ & \text { Back Item, Knee } \\ & \text { Method, Fitting }\end{array}\right] \\ R_{0132}=\left[\begin{array}{ll}\text {Front and Back Relationship, } & \text { Front Item, Sensor Component } \\ & \text { Back Item, Thigh } \\ & \text { Method, Fitting }\end{array}\right]\end{array}\right.$

Applying Eq. (9) to the deficiency relation element $R_{02}$, the divergent analysis results are:

$R_{02}=\left[\begin{array}{lll}\text { Left and Right Relationship, } & \text { Outer Side Item, } & \text { Outer Main Body } \\ & \text { Inner Side Item, } & \text { Side Support Component } \\ \text { Method, } & \text { Encasing }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{021}=\left[\begin{array}{ll}\text {Left and Right Relationship, } & \text {Outer Side Item, Side Support Component} \\ & \text { Inner Side Item, Outer Main Body} \\ & \text { Method, Fitting}\end{array}\right] \\R_{022}=\left[\begin{array}{ll}\text {Left and Right Relationship, } & \text { Edge Item, Binding Component } \\ & \text { Inner Side Item, Side Support Component} \\ & \text {Method, Fitting}\end{array}\right]\\R_{023}=\left[\begin{array}{ll}\text { Encasing Relationship, } & \text { Outer Side Item, Outer Main Body } \\ & \text { Inner Side Item, Side Support Component } \\ & \text { Method, Integrated}\end{array}\right] \\ \end{array}\right.$

$\mapsto$$R_{0221}=\left[\begin{array}{lll}\text { Left and Right Relationship, } & \text { Outer Side Item, } & \text { Side Support Component } \\ & \text { Intermediate Item, } & \text { Inner Material } \\ & \text { Inner Side Item, } & \text { Side of the Knee Joint } \\ & \text { Method, } & \text { Fitting }\end{array}\right]$

Applying Eq. (9) to the deficiency relation element $R_{03}$, the divergent analysis results are:

$R_{03}=\left[\begin{array}{lll}\text { Encasing Relationship, } & \text { Outer Side Item, } & \text { Anti-slip Component } \\ & \text { Inner Side Item, } & \text { Human Thigh } \\ & \text { Method, } & \text { Fitting }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{031}=\left[\begin{array}{l}\text { Encasing Relationship, Outer Side Item, Binding Component } \\ \text { Intermediate Item, Anti-slip Component } \\ \text { Inner Side Item, Back of the Lower Limb } \\ \text { Method, Fitting }\end{array}\right] \\ R_{032}=\left[\begin{array}{l}\text { Encasing Relationship, Outer Side Item, Outer Main Body } \\ \text { Intermediate Item, Interior } \\ \text { Inner Side Item, Fitting} \\ \text { Method, Fitting }\end{array}\right] \\\mapsto R_{0321}=\left[\begin{array}{l}\text {Encasing Relationship, Outer Side Item, Anti-slip Component } \\ \text {Inner Side Item, Thigh, Calf } \\ \text { Method, Fitting }\end{array}\right]\end{array}\right.$

Applying Eq. (9) to the deficiency relation element $R_{04}$, the divergent analysis results are:

$R_{04}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Decorative Pattern } \\ & \text { Back Item, } & \text { Outer Main Body } \\ & \text { Method, } & \text { Covering }\end{array}\right] \mapsto$

$\left\{\begin{array}{l}R_{041}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Decorative Pattern } \\ & \text { Back Item, } & \text { Binding Component } \\ & \text { Method, } & \text { Covering }\end{array}\right] \\ R_{042}=\left[\begin{array}{lll}\text { Front and Back Relationship, } & \text { Front Item, } & \text { Decorative Pattern } \\ & \text { Back Item, } & \text { Outer Main Body } \\ & \text { Method, } & \text { Embroidery Integrated }\end{array}\right]\end{array}\right.$

Taking sports knee protectors as an example, the following factors should be considered during the convergence of the design scheme:

(1) Safety and Protection: The primary concern is ensuring that the knee protector remains resilient under normal use, without fatigue or deformation. All components must withstand the user's lower limb movements without causing any harm to the body, thereby ensuring the user's safety. Additionally, the knee protector should provide effective protection against impacts and buffer the knee joint during flexion and extension movements, preventing injuries from sudden pressures.

(2) Convenience and Comfort: Given that the user group consists of post-90s basketball enthusiasts, and the primary usage environment includes basketball activities or other daily activities, the knee protector should be easy to use and wear. It should minimize restrictiveness while ensuring a good fit and comfort, catering to the needs of both sports and everyday activities.

(3) Slip Resistance: During physical activities, knee protectors can easily slip or move due to various factors, which not only diminishes the user experience but also reduces their protective efficiency. Therefore, the knee protector should possess anti-slip features to maintain a close fit with the knee, maximizing its protective function.

(4) Rationality: In terms of material selection and structural design, complexity should be avoided. The design should aim to be lightweight, enhance breathability, and improve the acceptability and manageability of the knee protector. Moreover, when innovating new functionalities, it's crucial to ensure their rationality and avoid redundant features.

(5) Aesthetics: The overall appearance should meet user needs and facilitate emotional expression to a certain extent. This is crucial for generating creative and user-appealing designs for sports knee protectors.

Creative Scheme Generation Process:

Applying Eqs. (10), (11), and (12) for permutation transformation to the deficiency material elements of basketball knee protectors, the results are as follows:

$T_1 M_{01}=M_{011}, \quad T_2 M_{02}=M_{022}, \quad T_3 M_{03}=M_{032},\quad T_4 M_{04}=M_{041}, \quad T_5 M_{05}=M_{052}, \\T_6 M_{06}=M_{062}, \quad T_7 M_{07}=M_{074}, \quad T_8 M_{08}=M_{081}, \quad T_9 M_{09}=M_{091}$

Applying Eqs. (10), (11), and (12) for permutation transformation to the deficiency relation elements of basketball knee protectors, the results are as follows:

$T_{10} R_{01}=R_{0121}, \quad T_{11} R_{01}=R_{0111}, \quad T_{12} R_{01}=R_{0112},\quad T_{13} R_{01}=R_{0113}, \quad T_{14} R_{01}=R_{0123}, \\T_{15} R_{01}=R_{0132}, \quad T_{16} R_{02}=R_{0221}, \quad T_{17} R_{02}=R_{023}, \quad T_{18} R_{03}=R_{031}, \quad T_{19} R_{03}=R_{032}$

where, $T_j,(j=1,2, \ldots, 19)$ represents the $j$-th transformation in the scheme generation process.

After analysis, it is found that through the above transformations, the deficiency event elements undergo conduction transformations, leading to improvements in functional deficiencies. Thus, by transforming the deficiency material elements and deficiency relation elements, the elemental model for the creative scheme of sports protective gear N can be represented as:

$N=M_{011} \wedge M_{022} \wedge M_{032} \wedge M_{041} \wedge M_{052} \wedge M_{062} \wedge M_{074} \wedge M_{081} \wedge M_{091} \wedge R_{0121} \\\wedge R_{0111} \wedge R_{0112} \wedge R_{0113} \wedge R_{0123} \wedge R_{0134} \wedge R_{0221} \wedge R_{023} \wedge R_{031} \wedge R_{032}$

Scheme: The style is semi-open, allowing for easy wearing and removal without needing to take off shoes, enhancing convenience. The main material is ABS hard material, integrated with flexible pressure sensors to provide feedback on users' movements. The side support components are integrally formed with the main material and use mechanical hinge devices to ensure knee joint flexibility. They provide landing cushioning and prevent abnormal knee flexion. The front compression component consists of three separate airbags, offering comfort and a close fit to the joint, constantly applying pressure to the patella, enhancing protection. The airbags are attached to an elastic material connected to the main structure. Four straps with Velcro fastenings ensure tightness adjustability. The overall style is simple, with decorative patterns on the main material that match the thematic style.

A preliminary conceptualization of the creative scheme, including sketching, model building, and effect drawing, is displayed in Table 3.

Sketching | Modelling | Effect |

|  |  |

Design Concept | Given that the main material is ABS, which is heavier and less permeable compared to knitted fabric, it is important to reduce the size of this component as much as possible while still meeting the support and component connection requirements. This adjustment is essential to ensure safety and permeability during use. | |

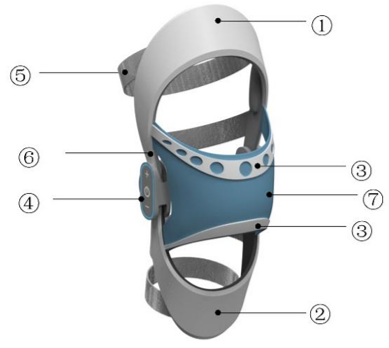

To further detail the function, structure, size, style, materials, and color of the sports protective gear, an overall optimization of the scheme was conducted. This process culminates in a presentation of the usage effects and detailed structure of the sports protective gear scheme. The product was rendered to visually represent its design, as shown in Figure 3.

A rendered image showing the product without the installation of silicone straps is presented, as depicted in Figure 4.

The overall dimensions of the product are illustrated in Figure 5.

The appearance of the product when worn is demonstrated in Figure 6.

Specific details of the product are showcased in Figure 7.

CMF analysis involves a comprehensive assessment of the product in terms of its functionality, comfort, and feasibility. The results of the CMF analysis are presented in Table 4.

Structural Schematic | Main Components | CMF Analysis |

| (1) Upper Frame (2) Lower Frame (3) Removable Silicone Strap (4) Intelligent Controller (5) Binding Strap (6) Support Rod (7) Outer Fabric | (1)(2) White ABS material, surface treated with rough sandblasting process (3) White elastic silicone, molded processing (4) Grey ABS material, surface treated with rough sandblasting process (5) Grey nylon Velcro, dyed processing (6) White Duralumin, surface treated with brushed processing (7) Lycra cotton blend material, fabric production process |

| (8) Main Pressure Airbag (9) Inner Lining Fabric (10) Front Knee Cushioning Airbag (11) Inner Material of the Main Frame | (8) Special fabric nylon, internal air filling (9) Lycra cotton blend material, fabric production process (10) Special fabric nylon, internal air filling (11) Grey EVA foam sponge, injection molding process. Lycra cotton blend material, fabric production process. |

4. Conclusion

This research addresses the challenges traditionally faced in the innovative design process of sports protective gear, which include over-reliance on designers' experience, low formalization, incomplete representation of design information, inaccurate expression of internal relationships, and limited expandability. The study summarizes a novel method for designing sports protective gear based on Extension Theory and validates this method through practical design applications.

By integrating extension innovation methods and ergonomics into the design process based on extension theory, the study achieves effective elemental modeling of sports protective gear and expression of product deficiencies. This approach allows for a comprehensive representation of sports protective gear, making explicit the relationships between its various components, thereby laying a foundation for the innovative design process of sports protective gear. The results demonstrate that this methodology not only enhances the design process but also contributes to producing more functional, user-centric, and innovative sports protective gear.

The data used to support the findings of this study are available from the corresponding author upon request.

The authors declare that they have no conflicts of interest.